What Is Aluminum Welding? “Explained”

What Is Aluminum Welding? is the topic of today’s article. Enjoy!

Welding aluminum is a difficult operation that must be done carefully. You can harm the aluminum if you aren’t careful. To weld aluminum successfully, you need to ensure that you have the appropriate equipment and expertise. It’s also critical to clean and free of pollutants the material before welding it.

Welding aluminum may seem daunting at first, but it’s not that different from welding other metals.

In this blog post, we will cover the basics of welding aluminum, from choosing the right process to cleaning and assembling the joint.

Safety is always important when welding, so make sure to read through safety tips before getting started!

There are many welding processes that work well with steel, but each has its own nuances when it comes to aluminum.

Aluminum is also more prone to impurities, so make sure you follow these steps to avoid any problems!

The most important thing to remember is that you must use a process designed specifically for welding aluminum otherwise you could end up with a weak and brittle weld.

What Is The Best Method For Welding Aluminum?

Some methods, such as electron beam welding, are specifically designed for welding aluminum and have a very precise heat-affected zone that can be easily controlled.

Laser beam welding is another great option for welding aluminum, as it is fast and produces clean welds.

There are a few different shielding gases that can be used when welding aluminum. The most popular choice is pure argon, which is often used for both gas metal arc welding (GMAW) and gas tungsten arc welding (GTAW). Mixtures of argon and helium are also common, while pure helium is generally the only source.

Can Aluminum Be Re-Welded?

Aluminum welding is possible, but it is a more delicate process than welding steel.

The alloys in an aluminum can be divided into two categories: those that can be welded more than once (5xxx series), and those that should only be welded only once (6xxx series).

The 5xxx series alloys are less sensitive to heat input, making them easier to weld. However, even they should only be welded once, as repeated welding can damage the metal.

The 6xxx series alloys are much more sensitive to heat, and should only be welded once. Repeated welding can cause the metal to weaken and may even lead to failure.

Can You Weld Aluminum With An Ac Stick Welder?

Welding aluminum can be done with an AC stick welder, but it is not the most effective way to do so. The best methods for welding aluminum are with an AC TIG welder or a DC TIG welder.

Can Aluminum Be Arc Welded?

Arc welding is a process that can be used to join two pieces of metal together. There are many different types of welding, and each one is best suited for a certain type of metal.

For example, arc welding is not the best method for welding aluminum. This is because aluminum is more prone to impurities than other types of metal. In order to weld aluminum successfully, the welder must clean it thoroughly.

Can You Weld Aluminum With TIG?

Welding aluminum requires its own technique and equipment. The welder and aluminum must be thoroughly cleaned. Aluminum is more prone to impurities.

- steps to follow:

- Use a solvent such as acetone or a mild alkaline solution like a strong soap to remove any oil,

- Use a stainless steel wire brush

- Assemble the joint and cover it if you won’t be welding it immediately.

- Always keep your aluminum dry and stored at room temperature

- Safety is another critical component to welding aluminum

Do You Need High Frequency To Weld Aluminum Stated Above?

Some people might think that you need high frequency to weld aluminum, but this is not always the case.

In most cases, setting the frequency to 200 Hz is good for most welding. However, if you need to do a few welds that need deep, precise penetration, then using a frequency of 400 Hz can be more effective.

Is MAPP Gas Hot Enough To Weld Aluminum?

MAPP gas is hot enough to weld aluminum. The reason you shouldn’t use propane or MAPP gas without an oxygen supply is that it doesn’t have a high enough temperature to weld aluminum successfully.

Too much oxygen or gas will cause the torch to blow out, therefore adding oxygen slowly while maintaining an optimal brazing flame is advised.

Can You Weld Aluminum To Steel?

Welding aluminum to steel is difficult because the two metals have different melting points. The aluminum will melt before the steel, which can cause the weld to fail.

Additionally, aluminum alloys can be more reactive than steels, which can lead to poor weld quality.

However, if you are careful and take the necessary precautions, it is possible to weld aluminum to steel.

You will need to use a welding process that has a higher heat output, such as MIG welding or TIG welding. You will also need to use a filler material that is compatible with both metals.

Can You Weld Aluminum With An Inverter Welder?

Inverter welders are perfect for welding aluminum because the arc voltage never truly goes through zero, making the AC arc more stable. While most other materials are GTA welded using DC, aluminum usually is welded using AC.

Can You Weld Aluminum With A Plasma Cutter?

Yes, you can weld aluminum with a plasma cutter. Plasma cutters are perfect for welding aluminum because they create clean, accurate welds without damaging the surface of the metal. They also quickly and easily weld aluminum workpieces together.

Why Is Aluminum Welding Difficult?

Aluminum welding can be difficult because aluminum and its compounds are corrosion-resistive and thermally non-conductive.

This means that drawing the heat away from the weld is critical to prevent excessive melting of unwelded material around the area being welded.

The other challenge with aluminum is that different aluminum alloys have different melting points, so it’s important for a welder to determine what alloy they are working with before performing any procedures.

Can I Weld Aluminum With A Gasless MIG Welder?

Yes, you can weld aluminum with a gasless MIG welder. However, it is not recommended to do so without a shielding gas as it could lead to poor weld quality.

Instead, it is recommended to use a flux core steel wire when welding aluminum with a gasless MIG welder.

This will help to ensure good weld quality and prevent any potential contamination.

Do You Need A Special Welder For Aluminum?

MIG machines can weld aluminum, but TIG equipment is typically used for more complicated welding tasks on aluminum.

This is because the TIG machine produces a higher-quality weld with less distortion. In addition, the TIG machine allows the welder greater control over the welding process, which may be useful when working with a material.

How Many Amps Does It Take To Weld Aluminum?

When welding aluminum, you need a high amount of amps because the metal is a good conductor of electricity.

When welding, you will need about 1 amp for every 0.001 inches of metal. This is if other things stay the same.

What Aluminum Is Not Weldable?

Aluminum alloys in the 2XXX group are not weldable using GTAW or GMAW because they are more likely to crack. However, alloys 2219 and 2519 can be welded using 2319 or 4043 filler metal.

Can Forged Aluminum Be Welded?

Welding forged aluminum can be done, but it is not recommended. The weld and heat-affected zone will both lose strength.

Welded aluminum also does not have good fatigue properties. This means that even if the weld seems to be strong at first, it won’t last long.

Can You Weld 1100 Aluminum?

Can you weld 1100 aluminum, specifically? The answer is yes – with the right welder and the right settings, you can join this metal alloy quite easily.

It’s a popular choice for boat building and other marine applications because of its corrosion resistance.

Do You Reverse Polarity When Welding Aluminum?

Do you reverse polarity when welding aluminum? This is an important question to ask, as it can impact the quality of your weld.

In general, most people will use alternating current (AC) when welding aluminum, as this creates a more stable arc. When using AC welding, the arc’s action will be reversed – with the electrode being positive and the workpiece being negative.

This will break up the oxide on the surface of the aluminum, making welding much easier.

Can You Weld Aluminum With Scratch Start TIG?

TIG welding aluminum is not possible if you use a scratch start TIG. This is because TIG welding is a slow, precise process that requires a stable, consistent current.

Can You Weld Aluminum With MIG?

MIG welding aluminum is faster than TIG welding. You can use the same settings as you do for DC welding. You don’t need a machine that can do AC/DC welding.

Why Does Aluminum Weld Crack?

Hot cracking, or solidification cracking, occurs in aluminum welds when high levels of thermal stress and solidification shrinkage are present while the weld is undergoing various degrees of solidification.

At What Temperature Does Aluminum Weaken?

At 600 degrees, aluminum alloys have lost half of their original strength (aluminum melts at around 1,260 degrees).

This means that they are more likely to deform or break at this temperature, as opposed to at a lower one.

It is important to keep this in mind when working with aluminum parts, as it can help you avoid potential failures.

How Much Weight Can An Aluminum Weld Hold?

Aluminum welds can hold a lot of weight! Aluminum alloys have a tensile strength of 10,000psi to 75,000psi, which means they can hold up to 10,000 to 75,000 pounds before breaking. This makes aluminum a great material for welding!

Final Thoughts On… What Is Aluminum Welding? “Explained”

Aluminum is a particular type of metal that requires its own technique and equipment.

For aluminum welding, we recommend using TIG or MIG to join the material.

You can also use gas tungsten arc welding (GTAW) but this process will take longer than either TIG or MIG methods because it’s an arc-based method rather than wire feed-based.

When welding aluminum, it’s important to clean the metal first. This will help you achieve a stronger weld and avoid any contamination.

Consider which process will work best for your application before you start welding! Aluminum is a great material for welding because it is lightweight and strong.

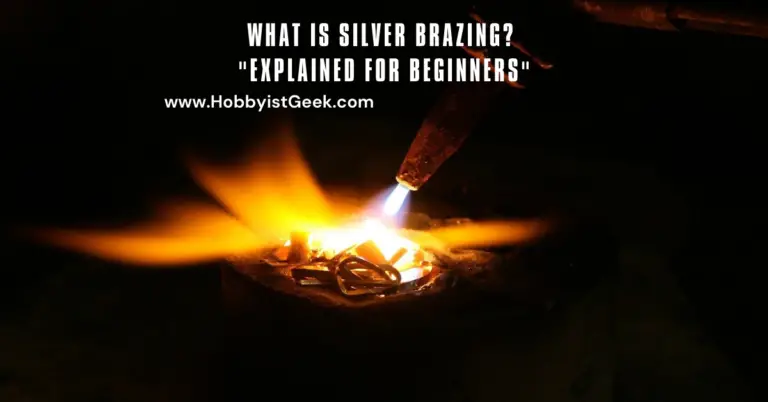

If you loved reading What Is Aluminum Welding? “Explained” you will love learning about Which Is Stronger Brazing Or Welding?!

Frequently Asked Questions

Can you weld aluminum without gas?

You don’t need to use shielding gas when arc welding aluminum. This is because the gas is meant to push away other gases that can contaminate the weld and make it unstable. If you weld in a vacuum chamber, you can avoid these problems and create a strong weld.

Can you weld aluminum with acetylene?

Yes, it is possible to weld aluminum with acetylene. By using a welding torch that has an oxy-acetylene flame, you can heat the aluminum until it is melted and then use the welding rod to join the two pieces together. It is important to make sure that the metal is clean and free of any contaminants before welding, as these can cause defects in the weld.

What is the best gas for welding aluminum?

There are several gases that can be used for welding aluminum. Some of the most popular ones include pure argon, argon-helium mixtures, and pure helium. Each gas has its own benefits and drawbacks, so it’s important to choose the right one for the job.

Argon is the most popular gas for welding aluminum. It is effective at preventing oxidation and corrosion, making it ideal for welding aluminum. Argon is often used for both gas metal arc welding and gas tungsten arc welding.

Sources

https://www.twi-global.com/technical-knowledge/faqs/aluminium-welding

ttps://makeitfrommetal.com/does-welding-aluminum-weaken-it/

- Jewelry Making Ideas: Seasonal Crystal Trends That Command Premium Prices - May 31, 2025

- Evil Eye Hand: Unveiling the Mystical Origins and Meanings - February 2, 2024

- Amegreen Amethyst Meaning: Discover the Hidden Magic! - February 2, 2024