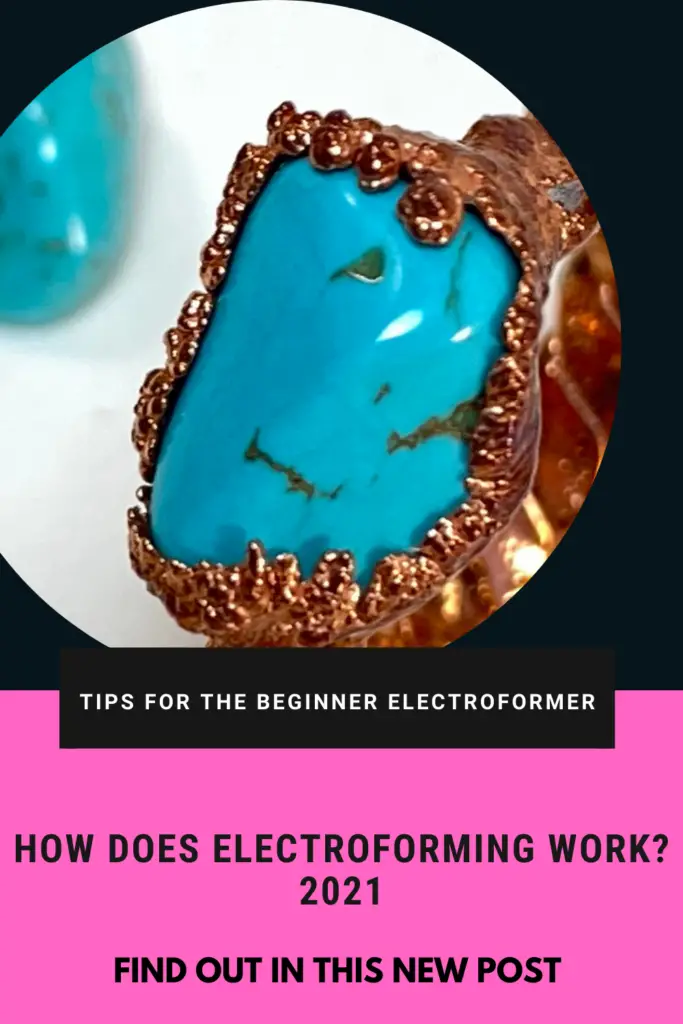

How Does Electroforming Work? For Beginners 2023

I Explain Just How Electroforming Works …

This article answers the question… How Does Electroforming Work?

When you first start electroforming, it is very difficult to understand how the process works and just how long this process is.

Even when you know what the process of electroforming is and what the correct electroforming procedure is and how each piece is created, there are still many questions that go through your mind.

The following article will give an overview of what electroforming actually is and answers the six common questions about this type of jewelry making.

Follow with me as we answer the question how does electroforming work?

The Answer To The Question… How Does Electroforming Work?

Electroforming is a metal working process in which current is passed between two electrodes, one of the objects is to be electroformed with copper conductive paint added to the object and the other object is a piece of copper pipe or copper sheet this is your Anode.

This process creates a layer of pure metal in this case a copper layer which is electrodeposited on the surface where metallic ions have been discharged by way of oxidation.

In electroforming, the metal can be grown as thick as the customer wants.

Who is the hobby of electroforming for?

Electroforming is a fantastic hobby for anyone who’s interested in jewelry making.

It’s also great for people who work with metal since electroforming allows you to create many different art pieces that would be impossible using traditional methods.

There are many benefits of this technique, but it can be hard to get started if you don’t know where to begin.

I’ve put together some tips and guidelines on how to get started with electroforming as a hobbyist jeweler/artist.

This article will show you what supplies, and processes are needed and the best ways to use them so your metal art projects turn out just right.

18 Most Important Things You’ll Need To Electroform

- Rectifier

- Alligator Clips

- Bus Wire

- Clamps

- Conductive Paint

- Electroforming Solution

- Replenishing Brightener

- Copper Anode

- Acid Safe Vassal

- Patina

- Crazy Glue

- Polyurethane Lacquer

- Jump Rings

- Rubber Gloves

- Filters

- Charcoal

- Jewelry Tools

- Copper Wire

What Is The Difference Between Electroforming And Electroplating?

First, the full name of electroforming is electrodeposition. Electroplating and electroforming are very similar processes in that both use electricity to deposit a metal onto a piece of jewelry or into an object.

The primary difference between them is what’s being deposited: with electroplating you are depositing a thin layer of different metals on top of something else; while with electroforming you are actually forming new metal around an existing object and transforming it into your design

What Metals Can Be Electroformed?

Electroforming only works with certain metals such as copper and silver nickel because they are more reactive than other metals like gold or platinum

Copper is the most popular metal and has been used for centuries because it’s easy to work with and inexpensive compared to other metals like silver or nickel.

The plating as well as metal finishing potential, leads to the conversation that additional material can be electroformed. Full plating, as well as metal finishing, can be carried out with:

- Palladium Nickel

- Silver

- Copper

- Gold

- Chromium

- Nickel

- Tin (bright or matt)

The resources each possesses have individual properties that make them appropriate for the creation of micro-precision fraction for a definite application.

Creating Your Workspace

As with any other work or job, electroforming jewelry requires precision, devotion and hard work if you are going to yield the desired results.

For this reason, you must take enough time to create your workspace to suit all of your needs, including comfort, before getting started.

What Are The Different Applications Of Electroforming?

Hobby related applications:

- Jewelry

- Art Sculpture

- Use of crystals and gemstone for healing and Spiritual power

- And many more applications

- The famous sculptor Dale Chihuly who creates his art in glass has said:

- “I was a glass sculptor major but decided to take classes in metal. In the metals department was a room with a primitive metal electroforming tank, very similar to a liquid bath.

- I didn’t know what it had been, and someone told me it had been called electroforming.”

Commercial applications:

- Molds

- Different Industry parts for the automotive and aerospace applications.

- The production of the original nickel stamper to make multiple CDs and DVDs for music, album, video or game disk is created.

- And many more applications

- The jewelry industry has been around for many thousands of years, and in the last 100 or so it has evolved into a multi-billion-dollar industry.

- What were once simple pieces of jewelry have turned into modern masterpieces that display great craftsmanship and artistry.

- However, one thing remains constant: people love to wear different types of jewelry as they make them feel more beautiful than ever before.

How To Take Care Of Electroformed Jewelry?

Why is my copper jewelry tarnishing?

Copper is a metal that tarnishes when exposed to oxygen.

There are many factors, including humidity, the oils on our skin, and exposure to other chemicals which will determine the speed and color of tarnish on your copper jewelry.

This can be very frustrating if you want your copper jewelry to stay shiny and new-looking for long periods of time after you have been wearing it.

How can I prevent my copper jewelry from tarnishing?

To help avoid this problem, there are several things you should do before even purchasing the equipment needed for electroforming copper.

Copper is a metal that naturally oxidizes over time.

To prevent the oxidation process, you need to coat your copper surface with different types of finishes which will help protect its condition and prolong its lifespan.

Despite what most people think, polishing and waxing doesn’t actually stop tarnish from forming.

This is because it only temporarily removes the discoloration on the surface!

What’s more important than preventing oxidation from occurring in the first place is protecting your jewelry after this happens.

How To Seal And Protect My Electroformed Copper Jewelry

Exposure to air or water causes the copper in your jewelry to tarnish.

This process is called oxidation, and it can be reversed with some simple steps.

If you have a piece of handmade jewelry that has been oxidized, follow these easy steps to return it back to its original finish:

Pour vinegar into a glass bowl

Submerge your copper jewelry

Add salt for a deeper clean

Leave the copper to soak for 15 to 20 minutes.

Your piece should be sparkling

Rinse/wash off all the vinegar

Dry it with a soft cloth

Final Thoughts

In conclusion, electroforming is a process that shapes metal into an organic shape.

To do this, the item to be shaped is submerged in an electroforming solution.

When electricity flows through the circuit, the copper ions help build up a layer of pure copper on the surface of your object.

Electroforming is an incredible hobby for anyone who’s interested in jewelry making and other art forms.

I hope you enjoyed this article How Does Electroforming Work?

It’s also great for folks that work with metal since electroforming allows you to form many different art pieces which may be impossible using traditional methods.

Electroforming: The Ultimate Guide Check It Out!

Michael

ELECTROFORMING | FUSED GLASS | METAL ARTIST

I’m documenting my electroforming journey step by step. I wish I had this information when I started my electroforming journey.

Pinterest

Facebook

Let Us Know What You Think

- Electroforming Conductive Paint, Where To Buy It, And How To Make It – The Ultimate Guide - April 24, 2021

- Copper Electroforming Solution Recipe - April 20, 2021

- Can You Electroform Polymer Clay? - April 13, 2021