How Electroforming Equipment Works | Dc Power Supply?

How Electroforming Equipment Works | Dc Power Supply?

Are you a beginning electroforming artist, or are you more experienced in the field of electroforming?

Either way, you’ll need to be 100% familiar with all aspects of your electroforming setup, from the solution to the power supply!

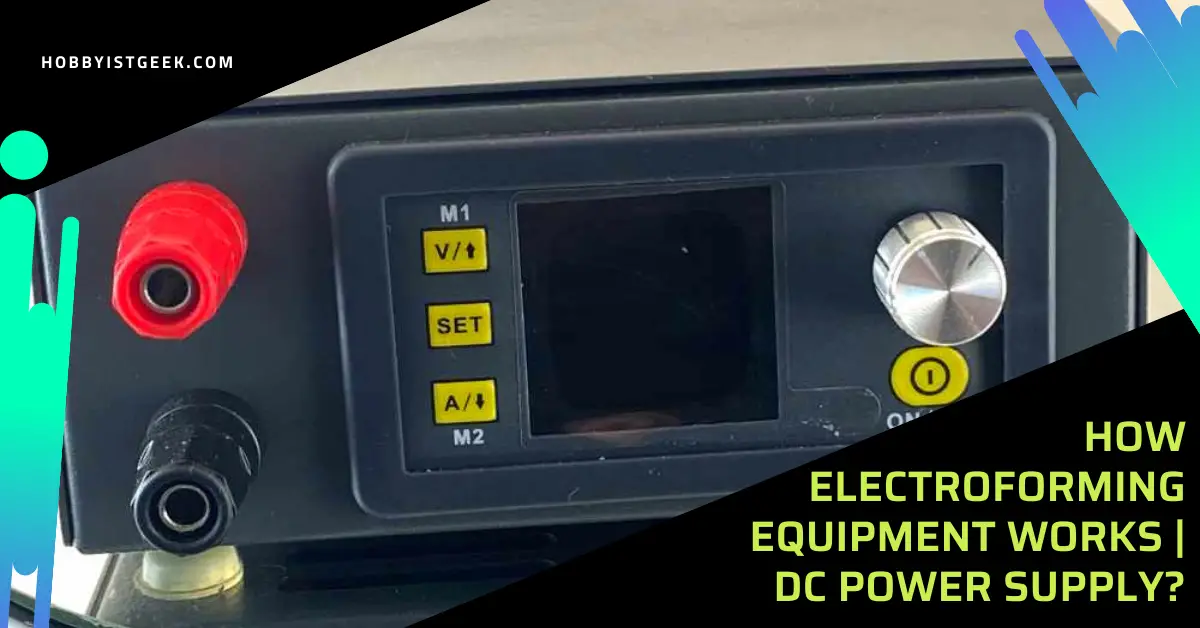

In this article our focus will lay on examining and explaining one of the most essential, yet advanced, parts of an electroforming setup, I’m of course talking about, the power supply!

How Does A Power Supply Work?

Answer to the question How Electroforming Equipment Works

Why is it necessary for electroforming?

A power supply generates and provides the electricity necessary for the electroforming process, without a power supply no electroforming can take place.

The power supply has many different variables to control, such as the current and the voltage settings, which should be set according to the surface area of the piece you’re working with.

Your power supply is set up by plugging the power cord into your wall outlet, and the two, black and red, wires to the front terminals, but more on that later!

More information on the different settings and the functionality of a power supply can be found later in this article!

As you might know, the power supply forms the heart of the electroforming process, without a steady and reliable source of electricity none of the beautiful results produced by electroforming would be possible.

Therefore, it’s very important to be familiar with the functionality and capabilities of your power supply!

In this article, we’ll teach you all about the power supply, what it can do, and how you should use it!

How Do You Use The Power Supply For Electroforming?

Obviously, the most important thing to know about your power supply is how to operate it in your electroforming setup!

In this paragraph, we’ll go over the different steps of setting, and connecting your power supply.

Before we can start running electricity through our setup, we’ll need to create our circuit.

For safety reasons, turn both the amperage and the current knob all the way to the left, the off position.

Now we’re ready to connect the appropriate wires, while your piece is in the electroforming bath, start by connecting the positive wire, generally red-colored, to the anode.

The anode is the conductive metal in our case copper that is submerged around the object, make sure to attach the wire above the electroforming solution, so that no direct contact is made between the copper wire and the electroforming solution.

After that connect the negative, black, wire to the cathode.

The cathode is the piece you’re trying to electroform, once again, make sure to attach the copper wire at the bus bar and not in the electroforming solution!

Now that we’ve created our circuit, it’s time to do some math!

Luckily, the mathematics involved isn’t too difficult, we’ll need to approximate the surface area of our piece and then set our power supply settings accordingly.

The way we do this is by using known geometrical shapes, such as spheres, cubes, or cylinders for example.

Use a ruler or any measuring device to estimate the measurements of your object, then use a formula for a basic shape to approximate the surface area of your object.

Once we know the surface area of our object we can derive what current setting we need to use, the general rule of thumb is 0.1 Amps per square inch, so for an object with a surface area of 5 square inches, we’ll be using 0.5 Amps for example.

Since this isn’t a math test and some shapes can be quite complex, especially when working with natural objects like leaves or flowers, it is recommended to use an online calculator to help you estimate the surface area!

A calculator you can use is: https://www.calculator.net/surface-area-calculator.html

With this knowledge, we’re now ready to bring our electroforming setup to life!

Slowly start turning the amperage knob on your power supply, until numbers start appearing on the LCD screen, now turn the knob to the required settings, note down the start time, and wait for the magic to happen!

Please Pin This Pinterest Pin To Your Pinterest Boards… Thanks

Power Output: How Much Do You Need For Electroforming?

We’ve already briefly mentioned it previously, but the importance of correctly setting your power supply for your specific project can’t be stressed enough!

The settings you’ll be using are based on the size and specifics of your project, but there are some things that always apply.

There are many options available in the world of rectifiers, 3Amp models, 5 Amp models, 10 Amp models all with their own current rating, but which one is right for you?

This is dependent on your budget, experience level, and working space, but as a beginning electroforming artist, a 3 Amp model should be perfectly fine, if you’re looking to advancing your electroforming skills or producing more or larger pieces however, it might be worth looking into some 5 Amp models!

Regardless of what model of rectifier you choose to buy, the 0.1 Amps per square inch rule will always apply.

You should keep this in mind when choosing the correct power supply for you, electroforming doesn’t require too much electricity and the prices of the different types of power supplies can increase exponentially when you’re looking at some of the higher-grade equipment.

So, choose your rectifier wisely, and keep the 0.1A per square inch rule in mind when doing so!

Will Your Power Supply Grow With You?

When picking the correct electroforming power supply for you, it’s important to realize that your electroforming skills will evolve, but your rectifier won’t evolve with you.

So, keep in mind, that while you might not be looking at big or complex power-draining projects now, you might be in a year and you want your power supply to be up for the task then, so it’s important to anticipate upgrades in your power supply!

It might be time to upgrade your rectifier when you’re ready to take on bigger projects.

Bigger projects don’t just focus on pieces with a bigger surface area, quite the contrary, rectifier upgrades are usually necessary when you want to electroform multiple pieces at once, or when you are looking to increase the size of your tank.

As you might imagine, increasing the number of pieces to be electroformed dramatically increases the surface area and circuit length we’re working with, thus increasing the required current and amps setting on your power supply!

Protection | Power Supply

When working with electricity safety is always priority number one on our list.

Electricity is inherently dangerous, and not treating it with the appropriate respect can have serious consequences ranging anywhere from a light electric shock to a devastating fire!

To avoid any of these dreadful prospects we should take a few safety precautions before proceeding to use our rectifier!

To start, one of the most important, and hopefully obvious, safety measures you should take is using proper wiring.

This means that you should avoid damaged insulation material, exposed copper wires, or frayed ends, as direct contact between an electrical wire and skin can cause some pretty painful shocks, but more importantly, exposed copper wires can start fires in a heartbeat and due to the lengthy nature of the electroforming process you might not be able to intervene before it’s too late!

It should go without saying, and it will be the case in most homes across the planet, that you should always ground your power supply and make sure that your home has something known as a ground fault circuit interrupter or GFCI, this will automatically shut down power when a problem, like too much current, or a short circuit, is detected.

Another important thing to note is that you should stay very clear of water when working with any electrical current, you might see this as obvious but even having remotely wet hands can increase the conductivity and thus seriously increase the consequences of a shock, it also boosts the chances of a short circuit.

Always be sure to disconnect your power supply when connecting things like wires, to prevent shocks and the unwanted transfer of electricity!

When working with electricity, it’s always good practice to wear rubber gloves and rubber shoes, doing this, you essentially ground yourself, and therefore you prevent any electrical shocks!

This might seem like an extensively long list of safety precautions, but most of them will fall in line with your common sense, and if you follow these safety precautions, you’ll be completely safe when executing your favorite hobby, electroforming!

Will Your Power Supply Fit Your Workspace? (Size And Weight)

Another, potentially important, thing to consider when choosing the perfect power supply for your needs, is the amount of space available.

Bench power supplies can be quite large and bulky, and they might occupy more space than is available, they can also be rather heavy which might present issues when you use your workbench for other things too, forcing you to clear it and thus move your power supply every once in a while!

The size and weight of a power supply is linked to its output capacity, a 10 Amp power supply, for example, could take a lot more space than a 3 Amp one.

In general, you’ll be looking at around 4 in X 4 in X 12in and 9lb or X10x10x30cm and 4kg for some of the smaller power supplies, but this can increase to up to twice the size and weight for some of the larger ones!

We recommend you measure your workbench to make sure that there’s enough room available to house your new power supply.

After all, there’s nothing worse than having to return your newly bought rectifier because it simply doesn’t fit!

Fan Noise

One of the biggest annoyances in using a power supply is the fan noise.

The fan noise might not seem like a deal-breaking issue at first, but when leaving the power supply on for longer periods, or perhaps overnight, during the electroforming process even a little bit of static noise can quickly turn into a game-changing issue. Therefore, it’s important to know what you buy in terms of noise!

It’s a very difficult task to figure out how much noise a certain power supply will produce before purchasing it, looking at the reviews of the online retailer can often be a good clue as to how much noise your system will produce.

If you value this issue highly, you can do your research on the specific brands of fans in the different power supplies to reach a conclusion that’s right for you!

One thing you should never do, and it should go without saying, try tampering with the system in any way!

Power supplies are delicate and complicated devices, with high currents running everywhere, a fan is necessary to keep the system safe and cool!

In this video you will see how to setup your power supply for electroforming:

Choose A Power Supply That Has Constant Current

Reading the title of this subheading, you might wonder what “Constant Current” and “Constant Voltage” even mean.

Let me explain very quickly before jumping into details, Constant Current and Constant Voltage systems are built into most modern power supplies for electroforming.

As we discussed earlier, power supplies are rated with specific current and voltage limits, 12V/1A for example, this means that the rectifier will work as expected within these limits.

Power Supplies for electroforming convert AC (alternating current) into DC (direct current) and we need to have a consistent current to obtain the best plating on our piece.

Cable Convenience

When working with electricity, cables will inevitably play a big role in your project.

This is why cable management is key when setting up your electroforming rectifier.

When electroforming, you’ll be working with multiple cables, of varying lengths and sizes, that’s why it’s good practice to follow some of the techniques mentioned below to ensure a clean, organized, and most importantly safe workspace!

First, it’s good practice to make sure your cables can move freely, without any knots or obstacles in the way!

Once you cleared your cables it’s best to position them in front of your power supply, to prevent any electrical issues affecting your power supply setup. Check out other power supply issues I covered in my article on electroforming troubleshooting.

It might not seem like an important aspect of electroforming, cable management is key to achieving successful results and an organized workspace!

What Is The Right Price For You?

It is easy to get lost in the world of power supplies, and as you will have noticed throughout this article, there’s plenty of options for you to choose from.

The way the world works, however, means that these options come at many different prices. Ranging from a mere $50 all the way up to $500 options if you want to, but how do you know what price is right for you?

First and foremost, it’s important to specify a clear budget for your power supply, as it’s easy to get lost in the wood of different options and prices.

Once you specified your budget you should start looking for the best options within that budget, when doing so pay attention to things like, capability, size and weight, and possibly fan noise as well!

It’s important to remember that, contrary to the marketing of many manufacturers, bigger isn’t always better, and there’s no need to spend big sums of money on power supplies when you won’t be using them to their full capabilities!

Popular Power Supply Manufacturers

To help you in your search for the best power supply for you, we’ve compiled a small list of some of the most popular power supply manufacturers among hobbyists and professionals alike.

- First of all, we’ve got Tacklife, Tacklife creates good-looking power supplies that’ll be more of an aesthetical enhancement to your workplace rather than a punishment.

Like all manufacturers listed here, Tacklife offers high-quality power supplies in many price ranges. Want to know more about Tacklife, visit: https://tacklifetools.com/products/

- Secondly, we’ve got a company under the name of Dr. Meter, this company offers the full range of power supplies, from the cheaper, less powerful ones, to complete power station machines for professional use, they have it all!

They look a little more conventional but their functionality is unmatched!

Want to know more? Visit: https://drmeter.com/collections/power-supply

- Another competitive power supply manufacturer can be found in the form of, Hanmatek, this company offers plenty of products on the electrical market, from power supplies to oscilloscopes, all with stunning quality and efficiency.

Hanmatek’s flagship product lies in their low power entry-level power supply found here: https://www.amazon.com/Adjustable-HANMATEK-HM305-Variable-Switching/dp/B0852JZQZR

- To finish our list of manufacturers, we’ve got skytoppower, based in China, just like most other entries on this list.

Also similar to the other entries is its wide variety of power supplies on offer, advertised with a stunning 40% increased efficiency!

More info can be found on http://en.skytoppower.com/

All these manufacturers are solid options when looking for a reliable power supply!

Power Supply Reviews

In this part of the article, we’ll examine a few individual power supplies in different power ranges!

3 Amps

Starting in the lower end of the spectrum, we’ll be looking at three similar options.

Both of these come at great price points and offer a great entry point to the electroforming hobby for those on a budget, whilst remaining reliable and solid!

https://www.smart-prototyping.com/DC-Power-Supply-LW-PS-303DM-0-30V-0-3A.html

https://www.elektor.nl/peaktech-6080-a-dc-power-supply-15-v-3-a

5 Amps

Moving up a notch, we have the power supplies for the committed hobbyist like you and me, with a fair balance between price and performance.

The options listed below are no exception to that and they are just what you need to get started!

10 Amps

Finally, we’re left with the big boys, the power supplies for the true professional, maximum power, maximum budget.

Picking any of these will ensure a lifetime of electroforming anything you might want in any quantity!

Final Thoughts For How Electroforming Equipment Works | Dc Power Supply?

All in all, choosing the best power supply for the job is a personal process, it involves many variables, and is very hard to do.

This article How Electroforming Equipment Works should be used as a guide for those who are embarking on their electroforming journey, and as a cheat sheet for the more experienced electroforming artists among us.

Thank you for reading, and good luck on your journey!

Electroforming: The Ultimate Guide Check It Out!

What’s Next?

Pin this post: Save this Pinterest Pin to your Pinterest boards, so you can visit us at a later time.

Leave a comment: I love to hear your feedback. Tell me on the contact page!

Share on Instagram or Facebook or Twitter: Please share it on social media and tag me.

Sources In MLA Format:

*, Name. “How To Choose The Best Electroforming Rectifier (+ Buying Guide).” Electroforming Artist, 4 Dec. 2020, electroformingartist.com/electroforming-rectifier/.

“About Us.” Dr.meter, drmeter.com/pages/about-us.

“Battery Testing System, Industrial Power Supply, Dc Regulated Power Supply, Battery Capacity Test.” Skytoppower, en.skytoppower.com/.

Creatives, Web Design. “15 Safety Precautions When Working With Electricity.” Atlantic Training Blog | EHS Training Downloads, 29 Oct. 2018, www.atlantictraining.com/blog/15-safety-precautions-electricity/.

“Electroforming Tutorial – Free Step by Step Guide to Making Copper Ele.” Enchanted Leaves, enchantedleaves.com/pages/electroforming-tutorial-free-step-by-step-guide-to-making-copper-electroformed-jewelry-learn-how-to-electroform.

“Home.” Calculator.net: Free Online Calculators – Math, Fitness, Finance, Science, www.calculator.net/surface-area-calculator.html.

“Tacklife: Tacklifetools the Future of Tools.” Tacklife Tools, tacklifetools.com/.

- Electroforming Conductive Paint, Where To Buy It, And How To Make It – The Ultimate Guide - April 24, 2021

- Copper Electroforming Solution Recipe - April 20, 2021

- Can You Electroform Polymer Clay? - April 13, 2021